The shaker screen is one of the most commonly used accessories on mud purification equipment, the role of the screen is through the high-speed vibration of the vibrating screen machine, and screening treatment of materials, to achieve the recycling of screening materials, often used in vibrating screen, cleaner, desander, desilter and other equipment supporting use.

The screening capacity and processing capacity of the vibrating screen have a direct relationship with the number of mesh of the vibrating screen cloth, which refers to the number of holes per square inch, the larger the mesh, the smaller the aperture, in general, the mesh X aperture (micron number)≈15000.

The size of the mesh determines the size of the screen aperture, and the size of the screen aperture determines the size of the largest particle of rock debris passed through the screen (we call it the sieve residue). The number of screen mesh we commonly use is 20,40,45,60,80,100,110,120,140,160,165,200 (unit is mesh), etc.

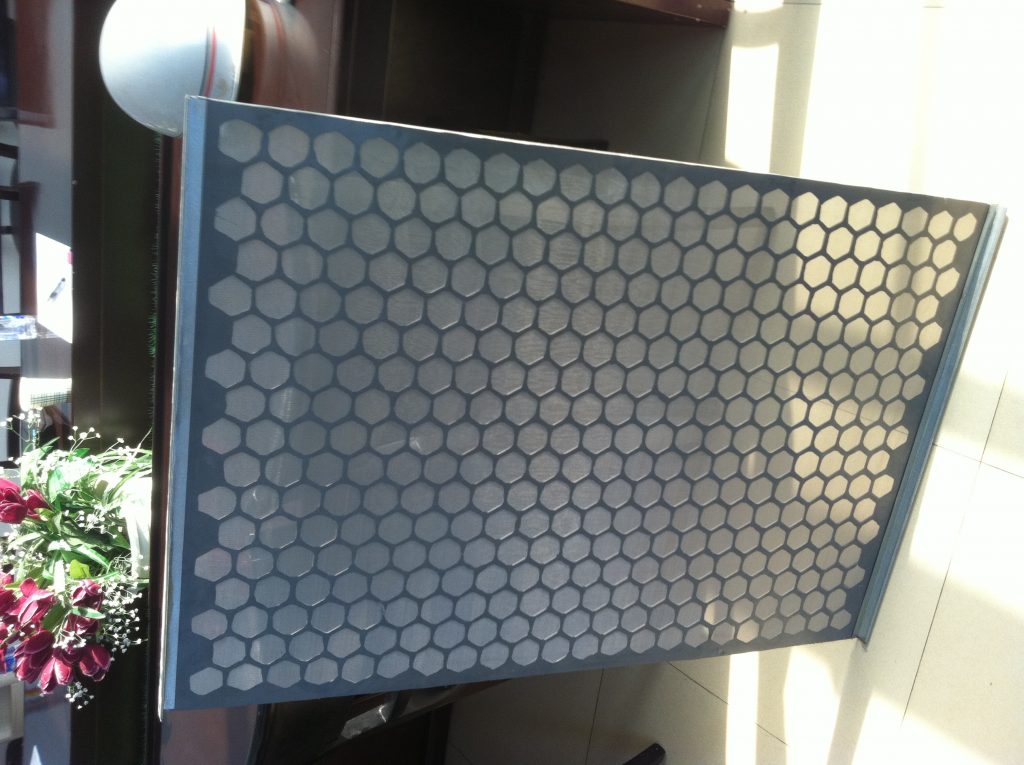

The common vibrating screen cloth types are divided into plate screen, wave screen, hook soft screen, and so on.

KOSUN can process various sizes of screens according to customer’s needs, and can also be adapted to Derrick, Brandt, Swaco, and other internationally renowned brands of shakers.