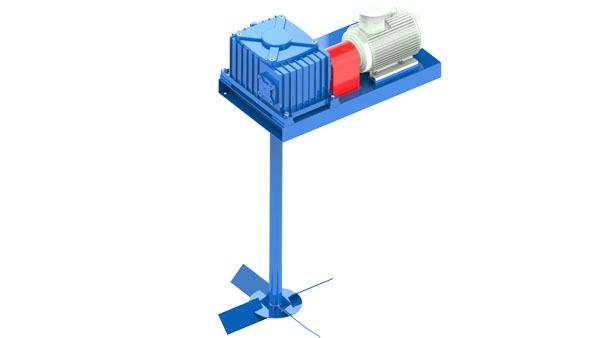

The motors in the mud agitator all use explosion-proof T-frame, 3-phase 230~460V, 1150 rpm, frequency 60 Hz; or 3-phase 190~380V, 958 rpm, frequency 50 Hz. Flexible coupling for motor The joint is directly connected with the reducer. A strong steel passport is mounted above the connecting shaft.

The solid mild steel shaft is connected to the reducer with a rigid coupling. In order to adjust the height of the impeller, a keyway is opened in the lower part of the shaft. The diameter of the shaft ranges from 38.1 mm to 88.9 mm, depending on the model, and the actual length of the shaft is determined by the user.

How to calculate the size and number of mud agitators

In the equipment currently in use, it is very likely that 75% of the mud agitators are installed improperly. The reason for this situation is either not understanding the correct size determination method, or not understanding the importance of selecting the size reasonably. The reasonable stirring amount calculated by each agitator is related to the given power and impeller diameter. The relationship between the mixing range that the impeller can reach and the specific gravity of the mud and the required power can be determined by calculation.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com